Motor

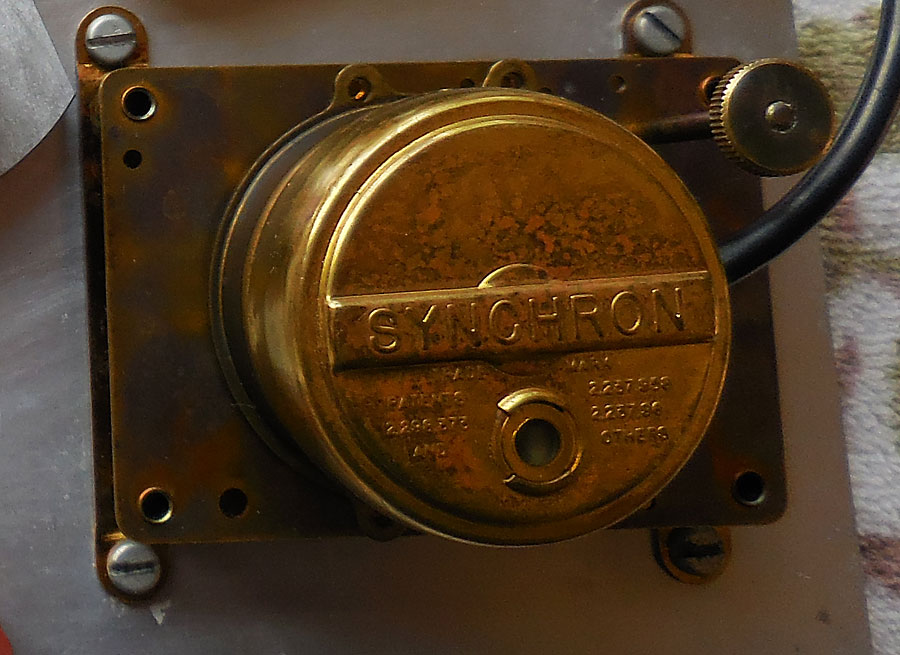

There are two parts to the motor. First the real motor is a synchronous motor that turns based on the frequency of the alternating current supplied to the clock. The United States uses 60 cycles per second and is very carefully controlled. Because the electrical windings in the motor were designed for the original 110 volt electricity and because the utility companies are continually raising the line voltage, in many cases above 125 volts, the motors tend to run hot.

The motor is still available. It is easily replaced. However, there is little to go wrong with it and they rarely fail. They fail by becoming noisy and running extra hot.

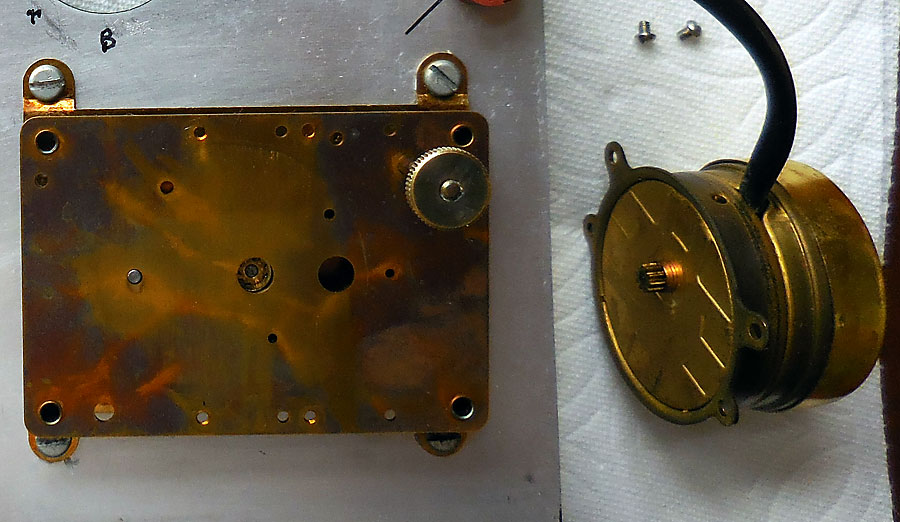

The second part of the motor is the metal gear train. The gears take the single rotation per minute and reduce the rotation to minutes and hours, rotating the second, minute, and hour hands correctly. Additionally there is a clutch which allows the clock hands to be set while not requiring the electric motor to turn.

Search for Hansen Synchron Clock Mechanism. The difficulty will be specifying the position of the set knob, the length of the hour and minute tubes (how far the nose sticks out), and the mount. There are many configurations.

The gear train can be cleaned using normal clock repair methods. I used an ultrasonic cleaner. The cleaned gears can be lubricated and reinstalled. The clutch should not be lubricated.