Playfield Clean and Touch Up, Reset Bank

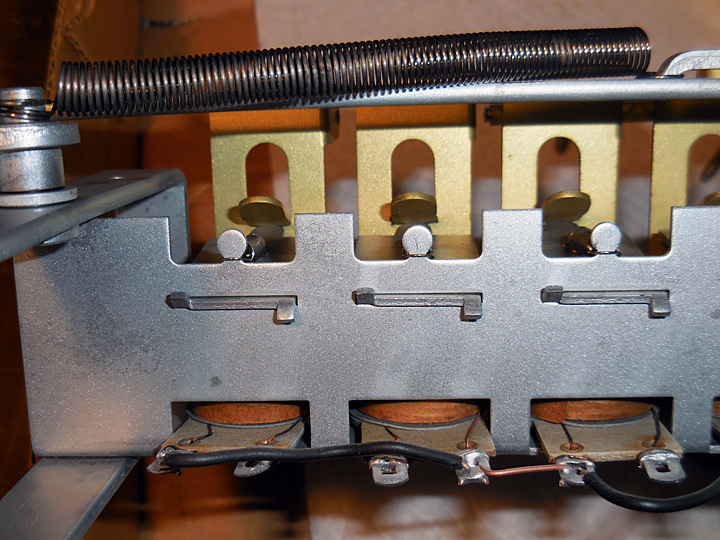

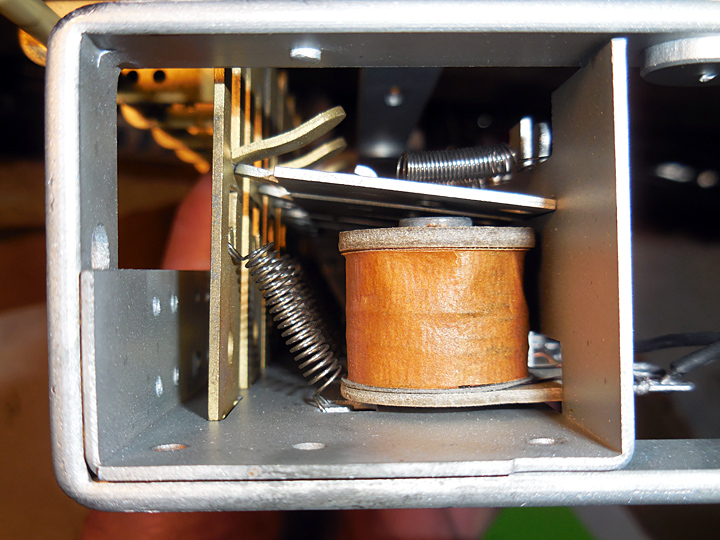

The reset bank is the first action to start a new game. All levers are reset until the action they measure happens. Cleaning it was very difficult. The plates on the individual relays were crimped to the frame as were the latch levers.

The relay plate is crimped to hold it in place and still allow it to latch. Cleaning the assembly without taking it apart is difficult.

Looking down the length of the reset bank, you can see the various plates, latches and springs. I was able to remove the springs and clean the frame and plates. However installing the springs, particularly the one on the left was difficult as there was little room. The crimps preventing disassembly were on the right frame, above the coil and on the bottom of the lever. Fun stuff...

The reset bank is clean. I need to reproduce the labels that were on the bar.

The playfield was dirty. I go through a sequence of cleaning agents, starting with the least invasive, hoping to find the least caustic that will actually clean. Starting with a damp cloth, I hope the dirt will come off. Then I progress through dishwashing detergent, isopropol alcohol, mineral spirits, naphtha, Methyl Ethyl Ketone (MEK), and finally acetone (Di Methyl Ketone). See my article on cleaning, something that is about 80% of the effort to restore a game. Another trick is to use Johnsons Paste Wax as a cleaning and waxing agent. The stuff works miracles. (Several years ago, there was a rumor that they were going to stop making the stuff. I immediately ran out and bought the stock at the local hadware store. It appears Johnsons decided to keep making the stuff.)

Since the playfield will be touched up first, it cannot be waxed. The wax will prevent adhesion of the paint. So we started with a damp rag. We went through the entire list and the dirt would not come off! I have never seen such a dirty mess and seen it so resistant to any cleaning solvent. It appeared MEK and alcohol were working but were not effective. Several days later I tried window cleaner and it worked the best of anything. There is also a lot of water damage that raised the grain and stained the wood. There was also some kind of oil that got into the grain of the wood. It will never be beautiful again, sadly.

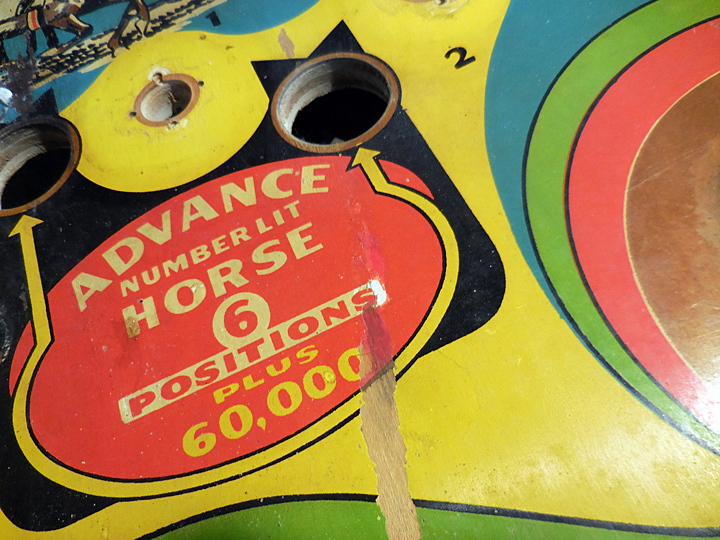

The eject hole throws the pinball and the ball causes wear when it lands. Here touchup has started, above and below the S. The black line was also continued but the water based pain ran in the wood grain. Later the black will be restored with a black alcohol based pen.

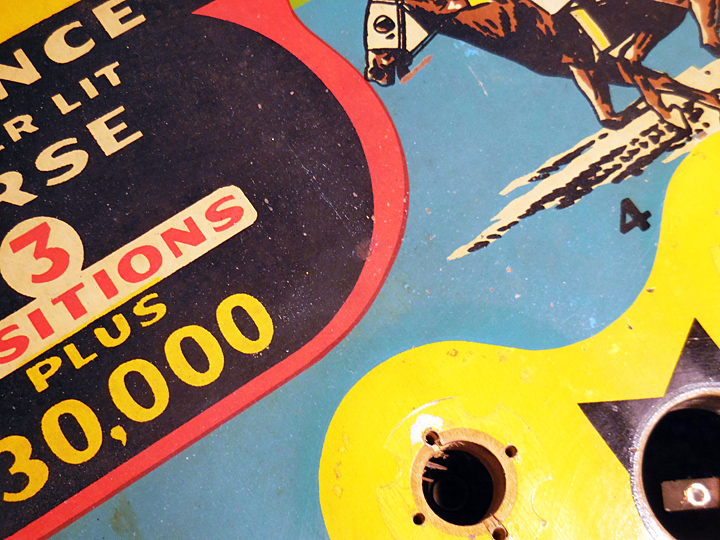

My wife does an exceptional job of color matching. She also has a technique where she puts multiple thin coats of paint, or washes to cover an area, thus preventing the normal raised pain strokes that cause the ball to wobble as it traverses the area. There is a small portion of missing black and red paint, half way between the 30,000 and the ground in front of the horse.

The playfield is clean and touch up has started. Later we will wax it. I will not go to the trouble of applying a clear coat to protect the paint. I expect the activity on this playfield by the ball will be slow and minimal. Keeping a playfield clean, waxing it once a year, and replacing the balls once a year will minimize the wear. (Balls will scrape against other metal objects or bash into metal, causing them to become pitted. Spinning will then act like sandpaper and cause excessive wear.