Evans Races Restoration

February 2010 restoration started

Disassembly is the reverse of assembly. Review the assembly pictures in reverse to see the order of disassembly.

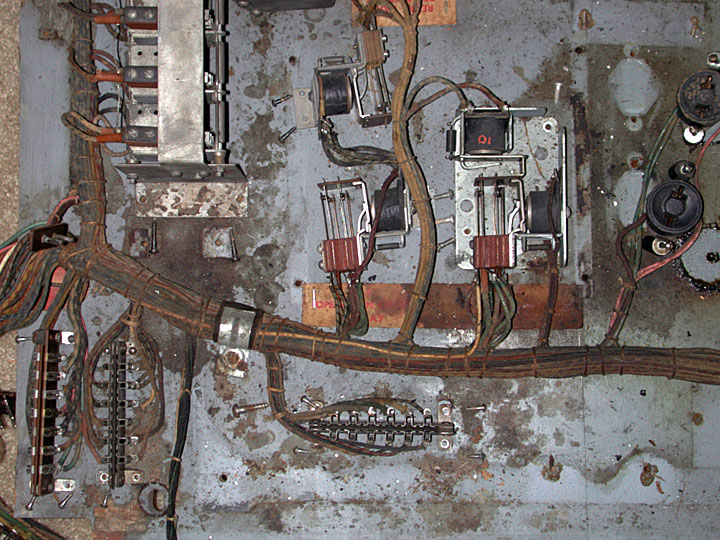

The following pictures show some of the highlights of the disassembly. Some pictures show how dirty and corroded the game was before the restoration started.

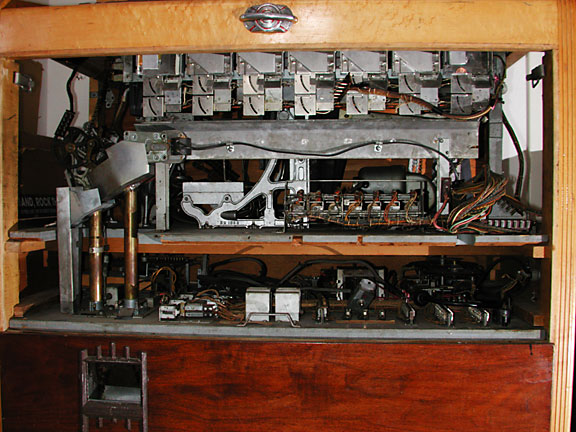

This is the view front the front of the cabinet, with the front door removed. Note the coin hopper at the bottom left where the coins are paid out and the tubes above it that collect the coins for payout. There are two boards shown here. The top board has the mechanical things mounted on it and a minimum of electronics and is responsible for moving the horses. It slides out the back of the cabinet for repairs.

The bottom board is full of electronic relays and a couple of other devices. The payout tubes are mounted on this board and the slicers that count off the coins of the winnings are mounted here. The board slides out towards the front of the game.

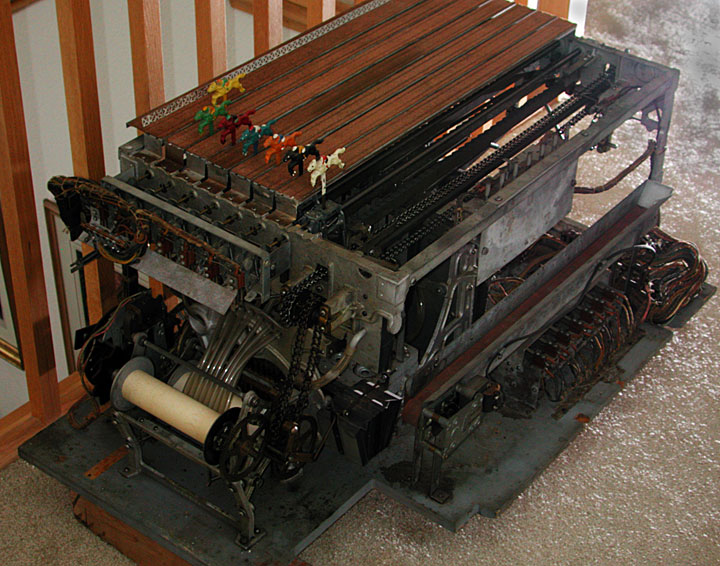

The mechanical board has been removed. The horses are still mounted as can be seen at the top. On the left is the player piano roll, along with a mechanism that reverses the direction of play. On the right is a tray and conveyer belt that collects the coins and drops them into hoppers for later payout.

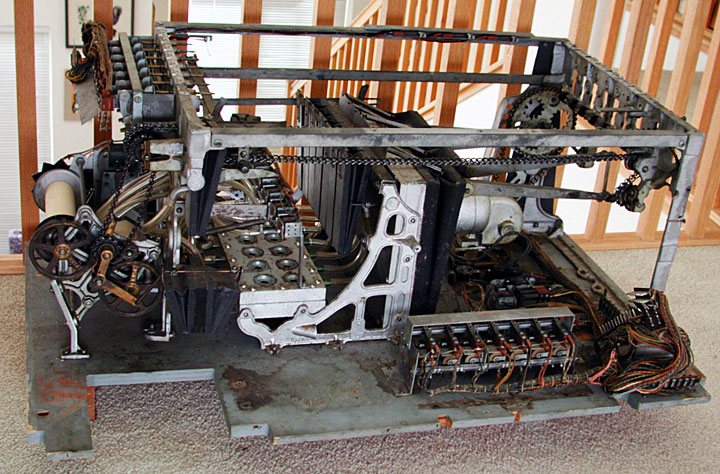

The horses and the mechanism that moves them have been removed. A conveyer belt and the buttons above it have also been removed.

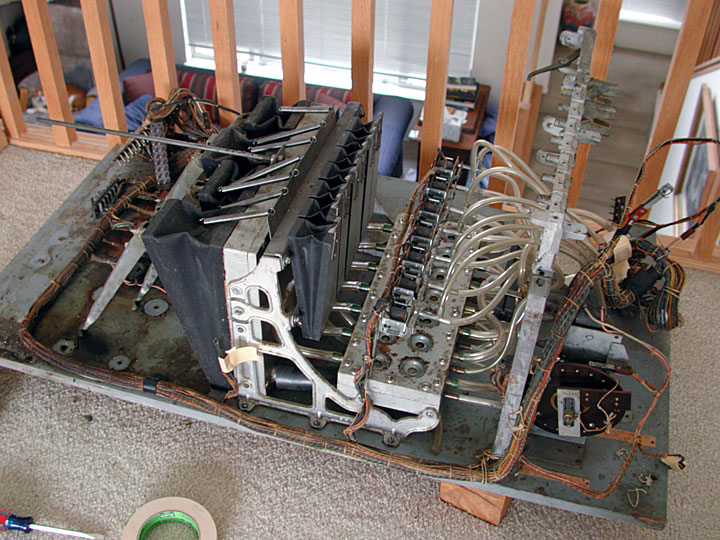

The pneumatics are left after most of the mechanical things have been removed. On the left are the pump bellows, in the middle are the smaller bellows that actuate the horses. The valve box has the holes in it with all the tubing leading from the valve box to the tracker bar. The piano roll mechanism on the right has also been removed.

This is the frame brace. It did not look like original equipment. Upon removal the reason for it was clear, the frame upright next to the motor was cracked. The open nature of the crack suggested a weakness in the casting in that area. I learned to TIG weld so that I could fix the aluminium frame. Thanks to TechShop for teaching me and providing the TIG welder. I got to get me one of those.

This is one of the horses along with its Musser brake. The purpose of the brake is to insure the motion of the horse is in the forward direction, that the horse does not back up during play, and to allow the horse carriage to be reset to the start at the end of the race. Note how the mechanism does not appear to be very dirty. The temptation is to spray with lubricant and hope it works.

Here is the Musser Brake from the horse above. Never run an antique coin operated game without completely disassembling the mechanism, cleaning it, and assembling it with fresh lubricant. The original lubricant became hard and literally crumbled off. Had the brake been lubricated, the crude would crumble during play and form an abrasive paste. This paste would cause rapid wear on moving parts, ruining the game and requiring expensive repairs.

The dirt has accumulated over the years, as expected for a game this old. The metal corrosion is caused by the use of electronic solder and the corrosive flux it included. The flux was not removed after the wires were soldered and the flux attached all the metal parts.