Evans Races Head Box Restoration

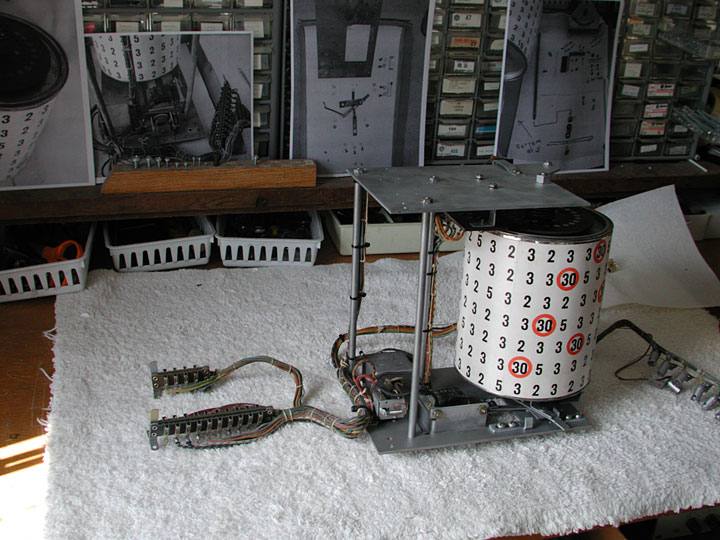

The head box on the Evans Races contains an odds drum mechanism and a score registration device.

The odds drum shows the odds for a particular horse winning and is spun during the race. Once it comes to a stop and the winning horse is determined, the game will pay out the correct number of coins based on the odds drum display. It consists of a paint can with a paper display of numbers wrapped around it. At the top are contacts that allow the game to determine the numbers displayed. At the bottom is a solenoid that causes the drum to spin.

The score registration device projects a number on the head box back glass. Upon winning, the brass wheel with silhouettes of numbers is incremented. When credits are played and horses bet upon, the brass wheel decrements.

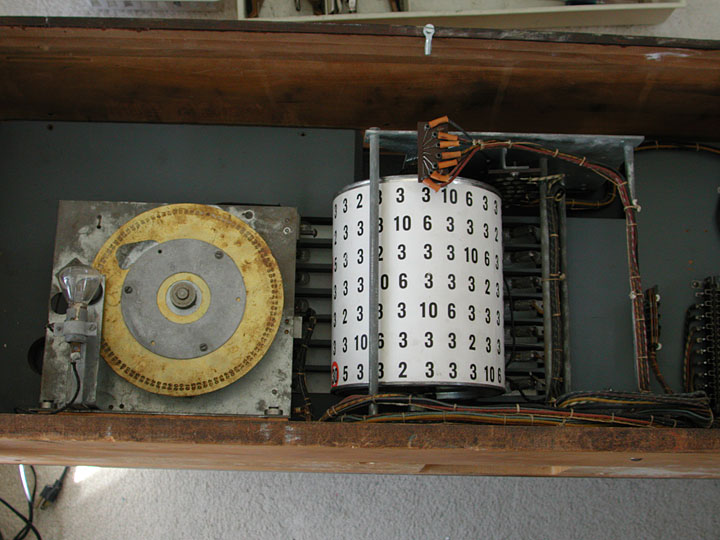

The score registration device is on the left and the odds drum is on the right.

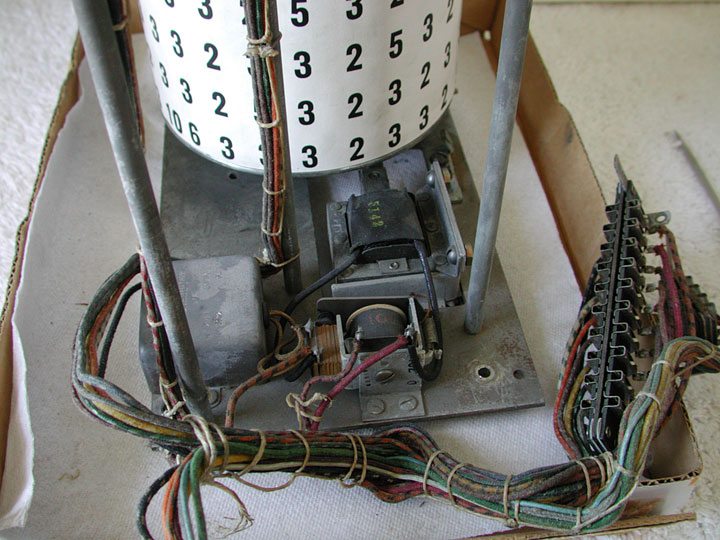

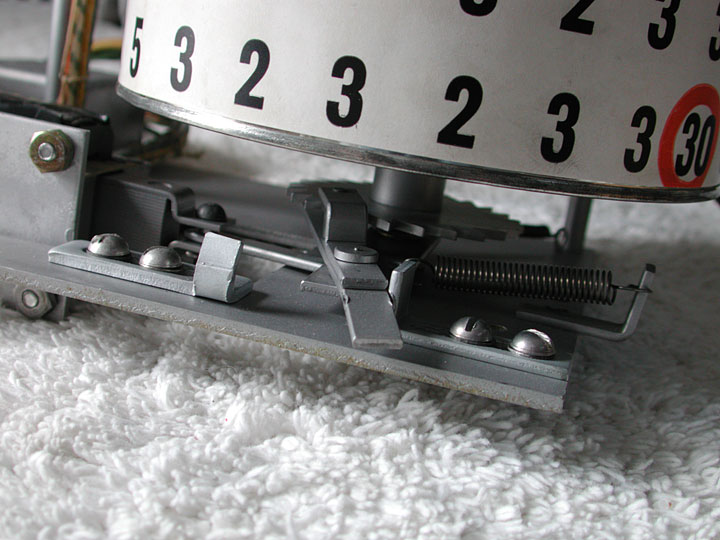

Beneath the odds drum is a large solenoid that releases a ratchet and spins the drum. When reset the solenoid allows a ratchet to engage and stop the spinning of the drum, locating the drum correctly at one of the columns. The smaller relay controls the large one and the box on the left is a 2 microfarad capacitor that suppresses the arcing on the small relay contact.

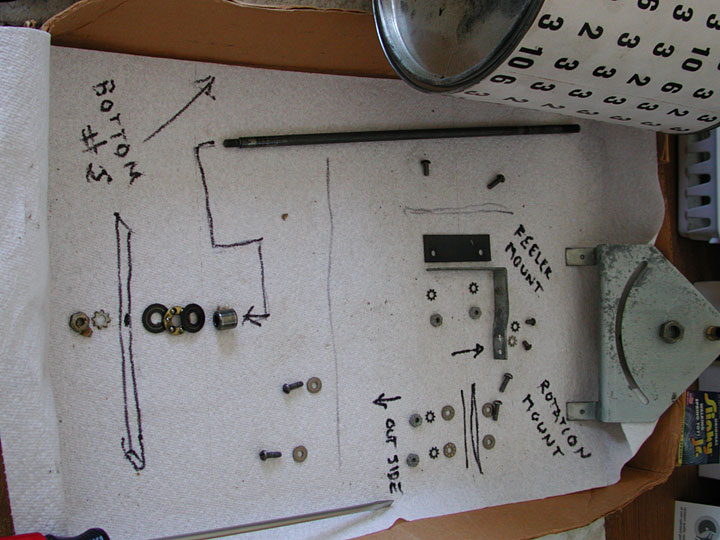

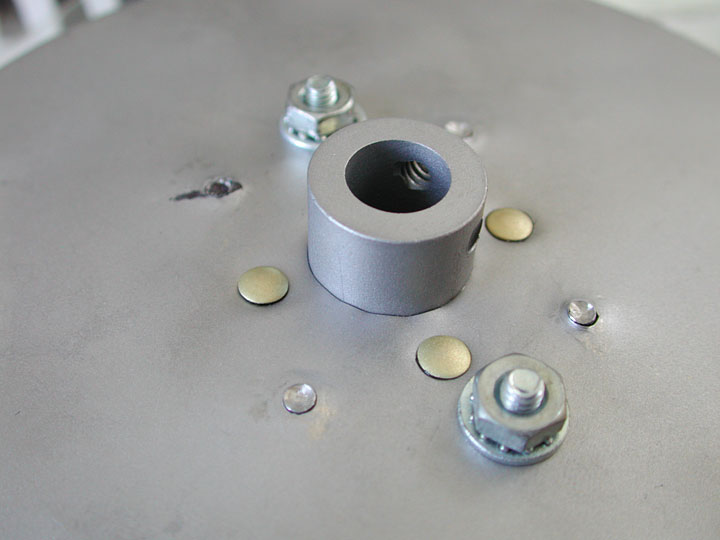

The odds drum is a paint can with pressed in end pieces. It spins on a metal axle and is designed to rotate freely. The base is on the left and shows a ball bearing race that supports the weight of the drum. Just above the race is a cylinder, next to the arrow, which is a needle bearing race, taking up the lateral stress of the rotating drum. There is one at the bottom of the axle and one at the top.

The sprocket on the bottom of the drum and the collar to the left are both held onto a brass tube by set screws. They have distorted the tube and could not be removed. The end cap of the paint can is reinforced with a metal collar and the collar is crimped onto the collar with the set screws. The end of the can is very flexible and distorted.

The collar threads were cut so close to the end of the collar that they showed through the casting. This and other evidence shows how poor the design of the odds drum assembly is.

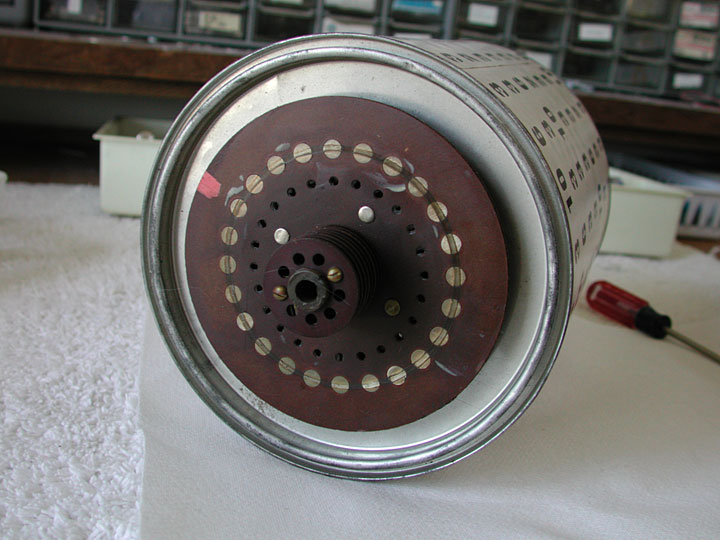

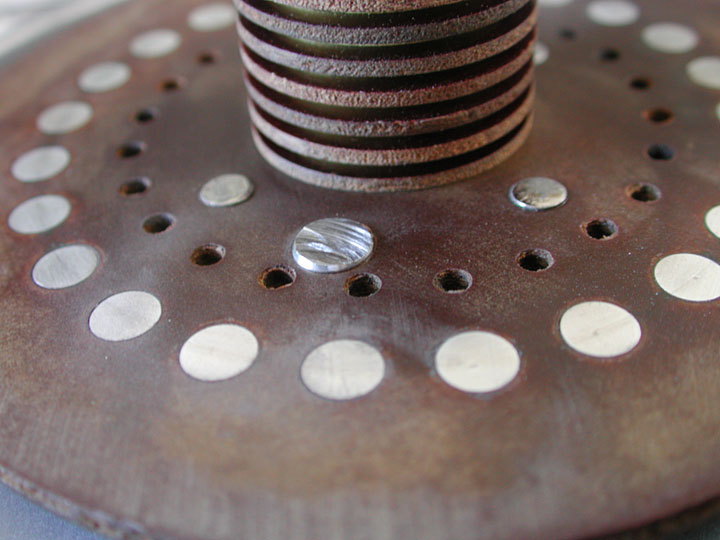

There are two sets of contacts on the odds drum which help the game determine the payout for the winning horse. Not only does the game need to know the winning horse, vertical, but also the odds for that horse to win, horizontal. The rotating contact stack is on top and has wires that follow the grooves, providing information on one of seven horses. The bottom contacts are feelers and determine where the drum stopped. The Bakelite assembly is riveted to the end plate of the paint can. The rivets needed to be removed to disassemble the contact stack.

The odds drum is a paint can with pressed in ends. There are two sets of contacts, one with fingers to feel the position of the drum, and the other as wire feelers that ride in grooves in a vertical stack that sense which horse is payout out.

This is the vertical stack of contacts disassembled. This should not be done unless absolutely necessary as it requires rivets to be removed. The rivets provide both spacing and attachment.

This is the inside view of the paint drum. It shows where the original rivets were located and drilled so the contacts could be removed. Also shown are the new bolts which reattach the contact plates to the end of the drum. Now the brass tube will be reinserted and the set screws tightened. The brass rivets attach the reinforcing plate to the thin metal of the drum end plate.

This is the other side of the drum plate, with the new screws that help attach the contacts. The heads of the screws have been trimmed in order to allow the wire feelers to make contact with the inner most ring.

The solenoid pulls in on the left, yanking the arm away from the toothed sprocket in the center. This causes the drum to spin. Upon the horses reaching a certain spot on the track, the solenoid releases, which causes the arm to reengage with the sprocket, causing the sprocket to position the drum correctly on one of the columns. Note the wear on the arm and the dents in the stops, attesting to the forces involved.

The odds drum is finished. Note the assembly pictures in the background, showing the assembly sequences.