Making New Parts or Fixing Broken Ones

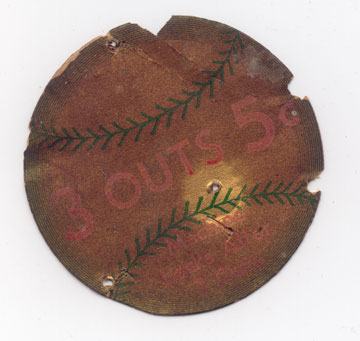

There is a sticker on the arch. I am not sure what it is, a tax sticker or a label of some kind. More research will be required so I an discover what it is and how to reproduce it.

The payment sticker will need to be reproduced as well because it is so dark and dingy. The original will be kept with the game in an envelope should the owner want it replaced. You can see the original condition in the center where the tack protected the original artwork.

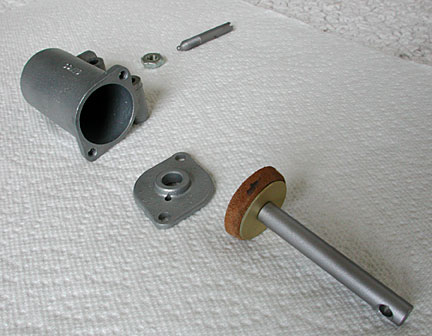

Damper with New Seal (leather)

The damper is now clean. Note how the seal has been replaced with new leather. It is increasingly difficult to find thin leather to replace worn parts in the games.

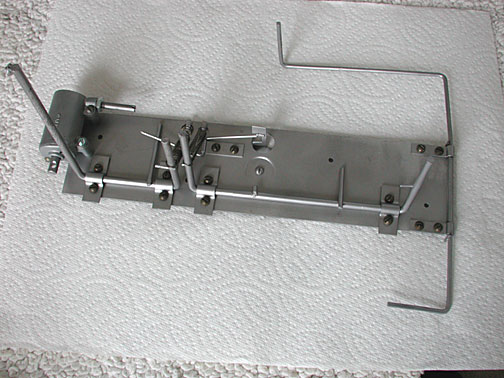

Levers

The levers have been cleaned and the new damper installed. The springs have been reformed so as to work correctly.

Welded Bolt

The pivot for the reset lever was so badly corroded that it was failing and needed to be replaced. The original pivot was nothing more than a screw head welded onto the lever. I did the same.

Ball Lift Pivot

Here is the cleaned ball lift pivot. The pits show how deep the corrosion was and how badly damaged the surface was. This also shows the new spring that was fabricated to replace the old one.

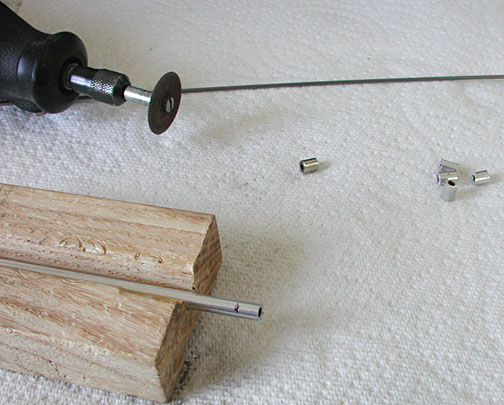

New Spacers or Stand Offs

Many of the original spacers were missing on the playfield. These spacers hold the ball guides up from the surface. I purchased aluminium tubing and some piano wire. I nested these so that the outside diameter matched the inside diameter of the next piece. Adding the piano wire helped hold the shape as a rotary tool with a cut off wheel is used to cut off spacers to length. I cut extras and then filed them to the correct length.

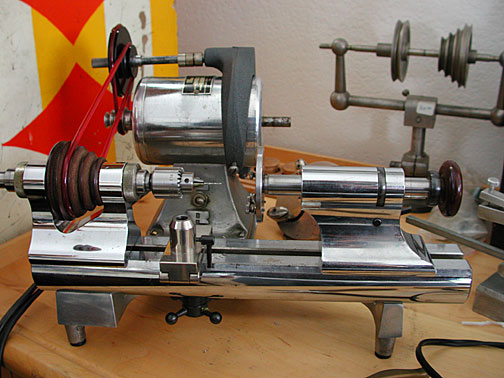

The gates that control the ball movement are held by pins, or nails, with very small holes in them. I used a clock and watch lathe my mother gave to me to drill the small holes in the sides of the pins. First I punched a flat spot in the side of the nail and then mounted it on the holding tool. The 58 drill was then used to make the hole.

New Pivot Pins

The old pin is shown below the new pin. The corrosion weakened the small sides of the pin and made them unusable. The heads are different and the new head will be rounded to more match the original.

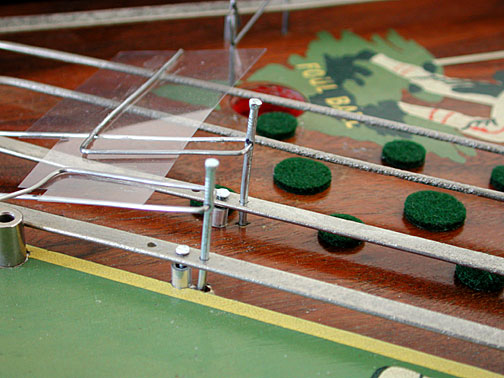

Gates as Found on the Game

The balls do not maintain their position when running the bases which results in incorrect scoring. At first it was not obvious if this problem existed in the original game or if it is a result of the gates being reproduced incorrectly. Because of this problem, the patent research was critical and helped tremendously in the restoration of this game. You can see how the gates work and how a home run is scored incorrectly in the mechanisms section.

I was determined to make the game play like a real game of baseball and spent a great deal of time trying to find various solutions. Because of the time spent and the intellectual challenge, this is one of the hardest restorations I have ever attempted. I find this ironic as this game is also one of the simplest mechanically and so there is just not that much involved, or so I thought!

The problem is that a double, triple or home run base runner rolls too quickly and needs to be slowed so as not to pass the released base runner that is held at any base. Or the question was how to make the base runner at any particular bag start rolling quickly. To some degree this is helped because the home run ball needs to travel farther than the base runner on first, second or third. Unfortunately the home run hitter has nothing to slow it and the held base runner needs to start quickly when released.

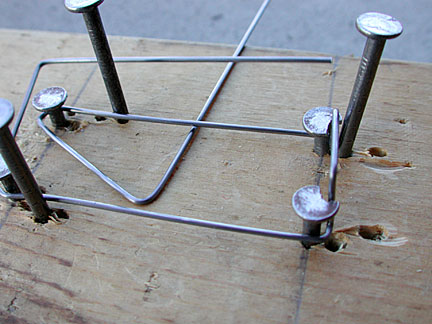

Making Gates

The gates needed to be made accurately. The original gates were made out of brass and did not work perfectly every time. I measured the correct distance and created a wood bending jig to insure the wire gates were perfect and identical. There are holes that hold the wire close to a pin or straight from pin to pin as the wire is bent around a pin. Also note the quarter portion of the nail heads on the right are cut out to make room for the vertical portion of the gate.

Slowing the Ball

The first modification was to make a gate like the patent describes. The patent shows a clear sheet that raises the gate much earlier and gives the held base runner a chance to get rolling. The first clue that the feature was not implemented like the patent on this game was the lack of nail holes where the pivots were required. I decided to try it anyway and implemented an arch to hold the pivot.

This approach did not work. In order to slow the ball enough, the home run ball needed to be almost stopped, just like the held ball. The result of the long clear gate did not effectively slow the ball enough. In fact, the home run ball needs to be slowed significantly in order to work correctly and this method did not even come close. Worse, if a ball is held or slowed significantly by a release wire and clear plastic extender, it might be held so much as to lose all momentum and become stuck. The ball has no standard amount of momentum to be used and therefore reliably adjust its speed.

On a previous game that I restored for the Thompson Collection, a Major League, the ball went under the playfield into a series of guides. The guides were designed to weave back and forth in a series of S bends to delay the roll of the ball, so a base runner on the surface was triggered to progress at each base with correct timing. I thought I might try the same concept.

In order to delay the ball, I strategically placed some green felt dots in the path of the ball. These caused the ball weave and to travel a greater distance, causing a sufficient delay. Careful placement made the game work correctly most of the time. However it looked very strange and certainly was not original! You can see the clear plastic used to lengthen the gate and the effect of a home run ball. It was added in yet another attempt to slow the ball and is similar to the original patent.

The only difference between this gate and the original patent is the pivot point of the plastic. The plastic should pivot about two inches to the right and should only pivot the clear plastic covering the two upper lanes.

Speeding Up the Ball

Since it was not easy to slow the activating ball, perhaps it might be possible to speed the released ball! Consultation with my wife and my father helped suggest and design this alternative. My father is a retired physicist and while his speciality was particle physics, he still remembers some basic physics. He is the best tinkerer I know.

Lynne is the president of the Sands Mechanical Museum and is an experienced Mechanical Engineer. Her specialty is high precision computer aided design of experiments destined for space, such as Gravity Probe B. (Gravity Probe B was designed to measure the differences between the physics described by Newton and Einstein.) She also remembers some basic mechanical engineering and was helpful in working with the gates.

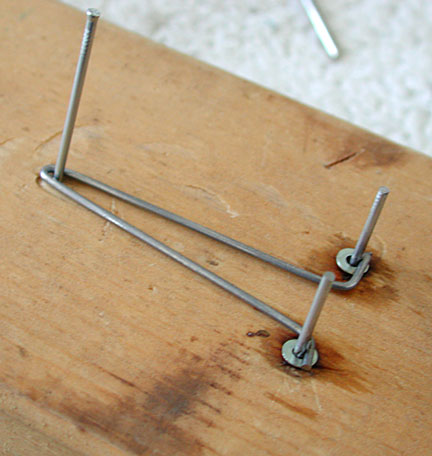

The design involved the ball in the gate being raised slightly. When the gate opens the ball falls off the ramp and therefore gains speed much more rapidly. The difficult part was having the ramp be so gradual as to still allow the ball to roll to the end of the gate and not stop in the middle of the ramp. The length of the gate is critical as the ball needs to be falling off the tip but still held in position by the square of the gate.

A second design criteria involved not changing any original parts in the game and being able to remove this new feature at any time. We wanted to be able to return the game to its original condition at any time.

The length of the ramp is critical. A V was bent and cut to length. Two small washers were silver soldered to the ends. The nails held the parts of the ramp in position while soldering. The ends of the arms were cut where they extended past the washers.

While this ramp did not fix the problem of the home run or triple base runner passing a runner already on base, it did make the game much more reliable. The game was delivered with the ramps in position.