Paces Races Restoration Progress April 20

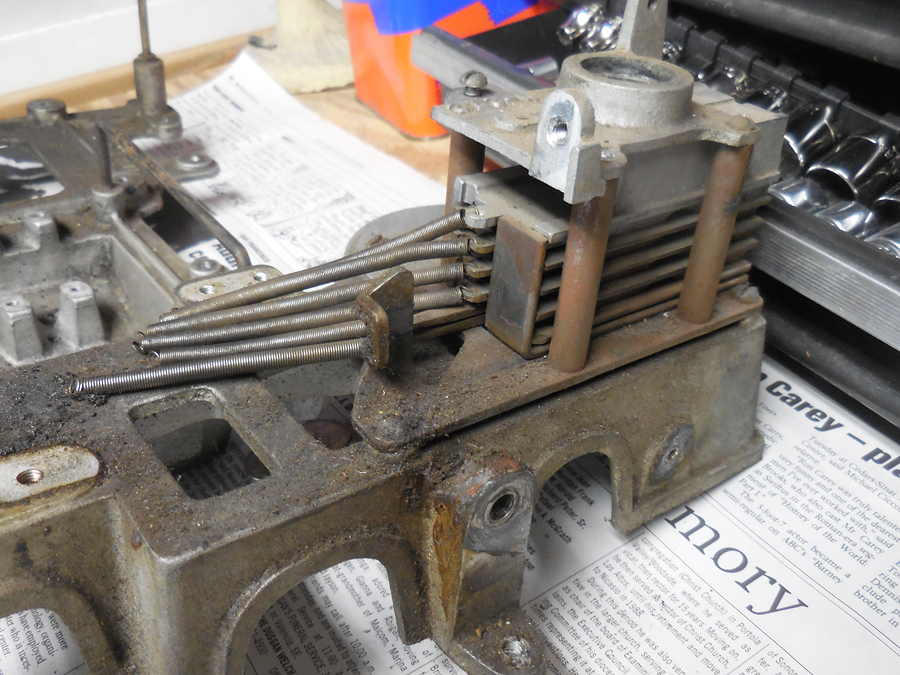

The slides are dirty probably because the money going through them is dirty. Money is one of the dirtiest things I know, right up there with the kitchen sponge.

The slides are varying in thickness, depending on how many coins are to be dropped.

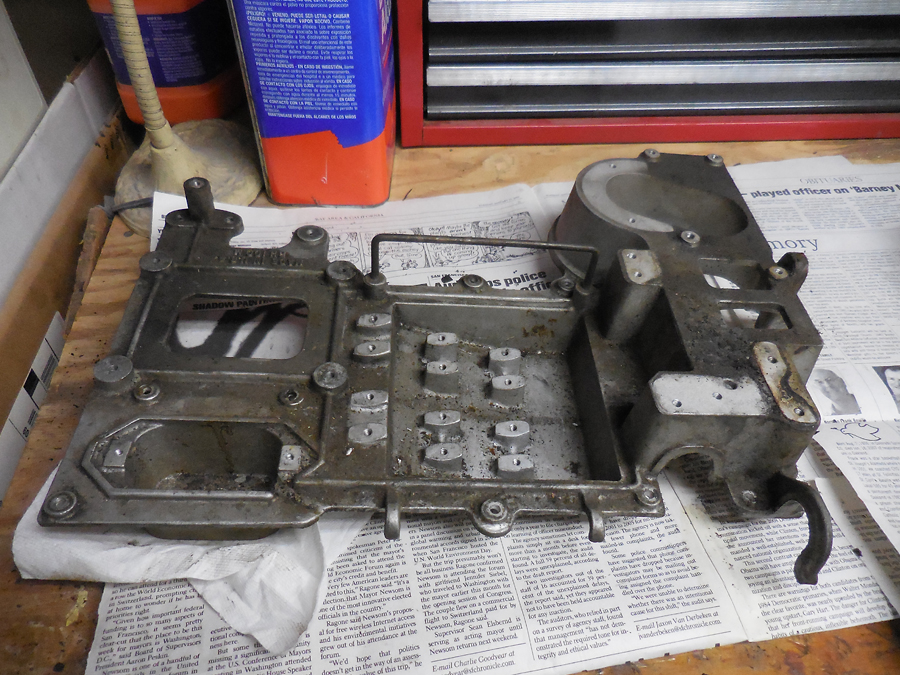

The casting is ready for bead blasting. The coin slides and bellows have been removed. The outlet for the motor is at the bottom left.

The parts are clean and ready to be installed.

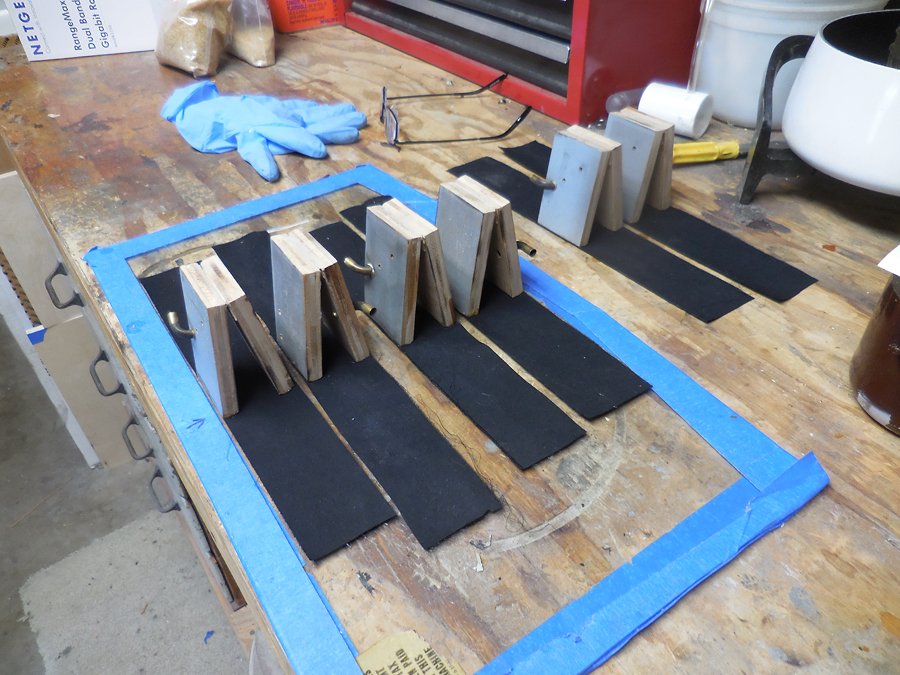

This is the sequence to recover the bellows. Both front edges are coated with hide glue. The edges are placed on the material and rocked back and forth to insure good contact. The wood is removed and the pattern of glue on the fabric is analyzed to make sure good contact is being made. Glue is reapplied and the wood is placed again in the same place. The glue is allowed to gel and harden slightly.

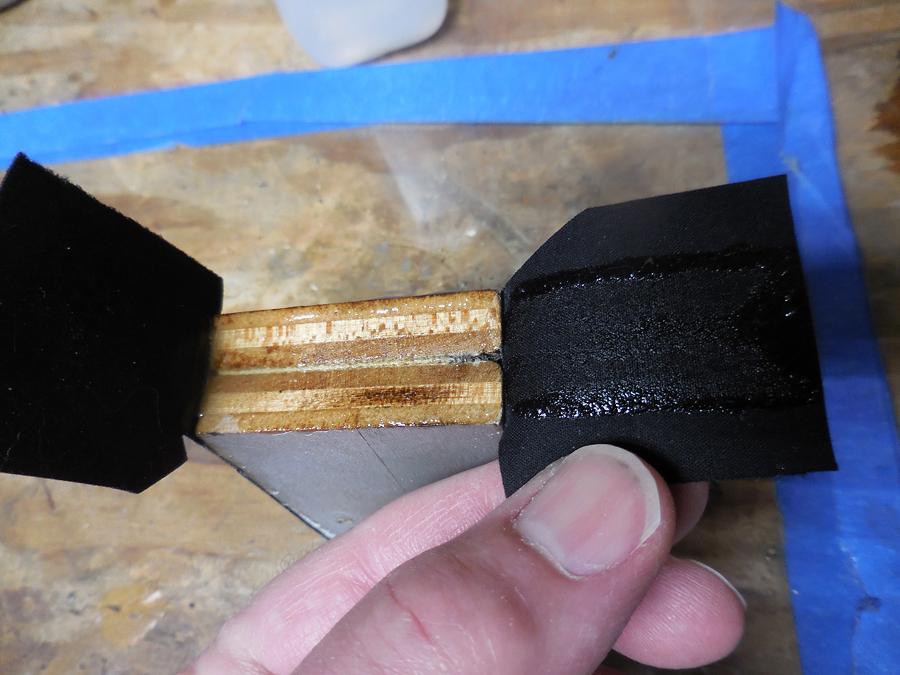

Note again the use of glass as a flat surface. The bellows are turned on their side and glue is applied to the top edge. The fabric is placed and removed. More glue is applied in areas where it was previously insufficient. The material is again applied. The bellows are turned over and the other side is glued. Care must be taken not to let glue get into the area of the hinge or to ooze along the inside edge of the wood. as it will cause additional wear and binding of the hinge.

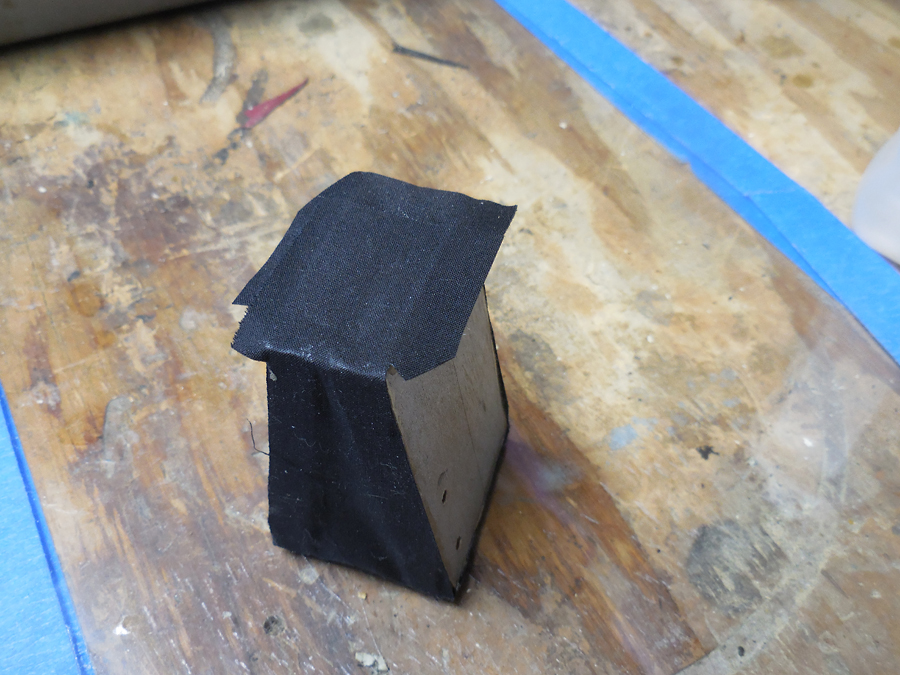

The end is glued and the material placed across the back. It is lifted again to make sure the entire surface of the fabric is making contact. The glue is allowed to dry.

The bellows have the back side glued. Once the glue is dry the edges are trimmed along the wood.

The bellows are ready for trimming.