Paces Races Progress February 14

The challenge was to find someone to weld the old crank so it was straight. At first I wanted to find a fabricator to take the bent crank and just fix it. It was difficult to find anyone to take on this challenge. Most of the welders and fabricators in my area, Silicon Valley, want to high end limited production work. I even tried a couple of auto repair shops.

One of the problems was the brazed part. This prevented welding because the braze material will melt first and contaminate the weld. I even considered re brazing it myself since I have a tiny hobbyist welding set. I also have a full sized MIG welder but worried this was beyond my ability.

I decided to disassemble the parts. I thought removing the sprocket might help reduce the complexity of the repair. I tried to remove the sprocket and it broke off in my hand! I placed the sprocket and remaining part of the axle in the jeweler's lathe and started to remove the brazing material. Happily the sprocket came off the axle. Now how to repair the crank?

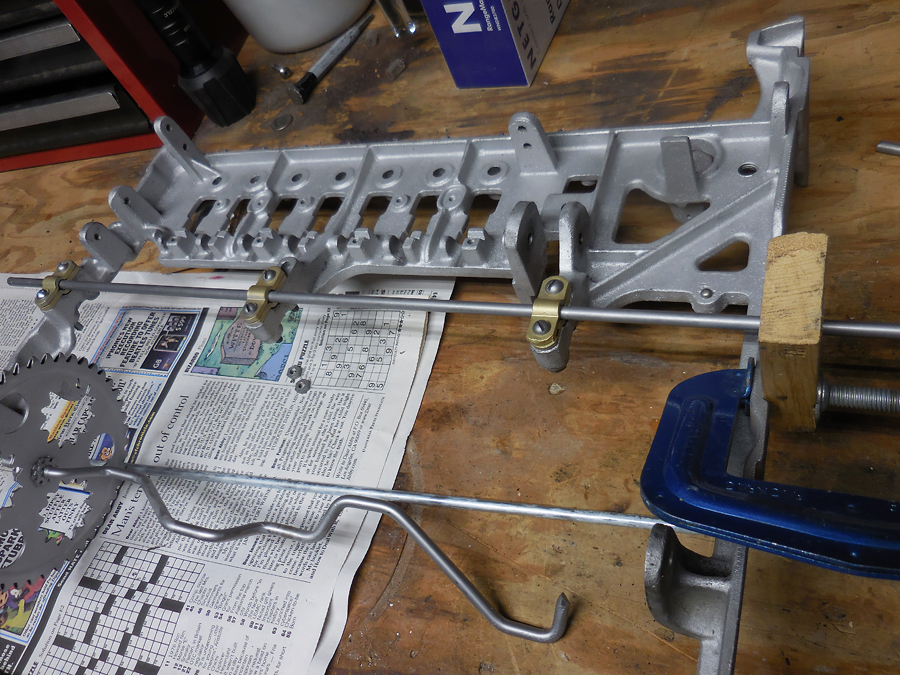

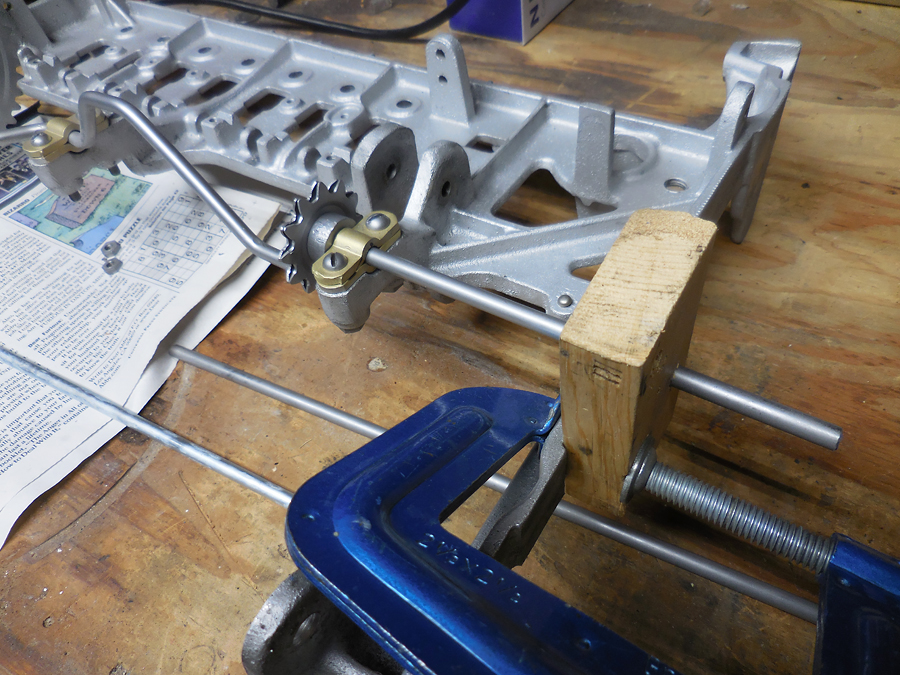

The pillow blocks are in line. Assuming an axle can be repaired, the end needs to be held in-line. I placed a straight rod through the pillow blocks and through a hole in the wood block. I clamped the wood block to the frame. Now I had a series of holes all in a line.

The wood block and the first pillow block are holding the repair piece in place. The rest of the crank is being held in place by the other two pillow blocks. Now I just need to weld it.

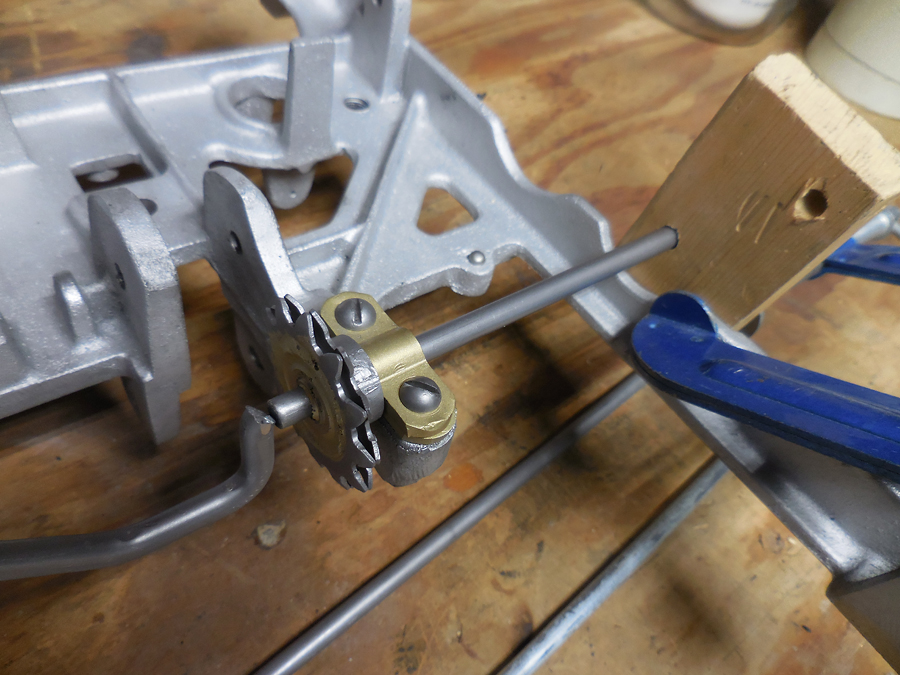

Here is where the weld is needed. Note the area around the weld is not contaminated with brazing material.

Here is the final fixture that holds all the pieces in line. The resultant weld was done commercially and while there is a tiny bit of wobble, it all works! Later the rest of the repaired axle will be trimmed depending on the crank that gets installed on the end.