Paces Races Restoration Progress January 21, 2020

I continued to work on the coin head, completing the disassembly. I found issues, some expected and some not. The brazing on the start lever is worse than I thought. The were some parts fabricated to replace some missing parts. And there were the normal frozen screws that required some encouragement to let go.

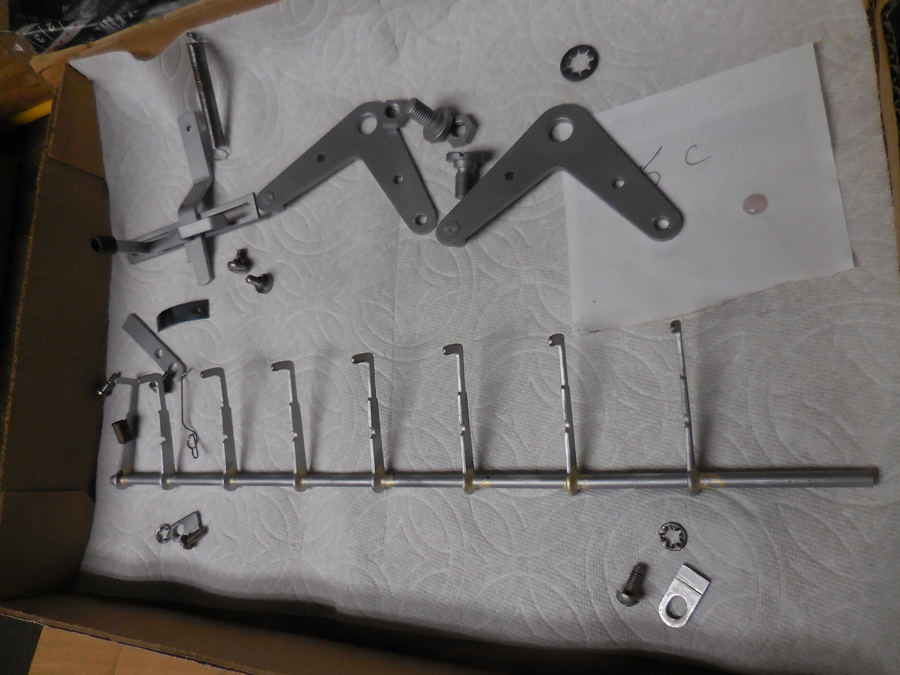

Here are some dirty parts as they are removed from the coin head. They are laid out in similar positions as found on the game. Note the shoulder screws in line with the hole in the L shaped actuator plate, in line with the bolt on the other side.

Here are the same parts after they have been cleaned. The large parts are bead blasted with glass beads and have a slight texture. The nuts and bolts are cleaned in an ultrasonic cleaner for 20 minutes in Alconox, a natural alkaline solvent. All parts are rinsed in tap water and blown dry with compressed air. Some of the dark parts, usually spring steel or iron, get a second bath in Citranox, a citrus acidic bath to help shine them a bit, removing the stain from the previous step. Springs are cleaned in a similar way and are carefully rinsed and dried by stretching the spring.

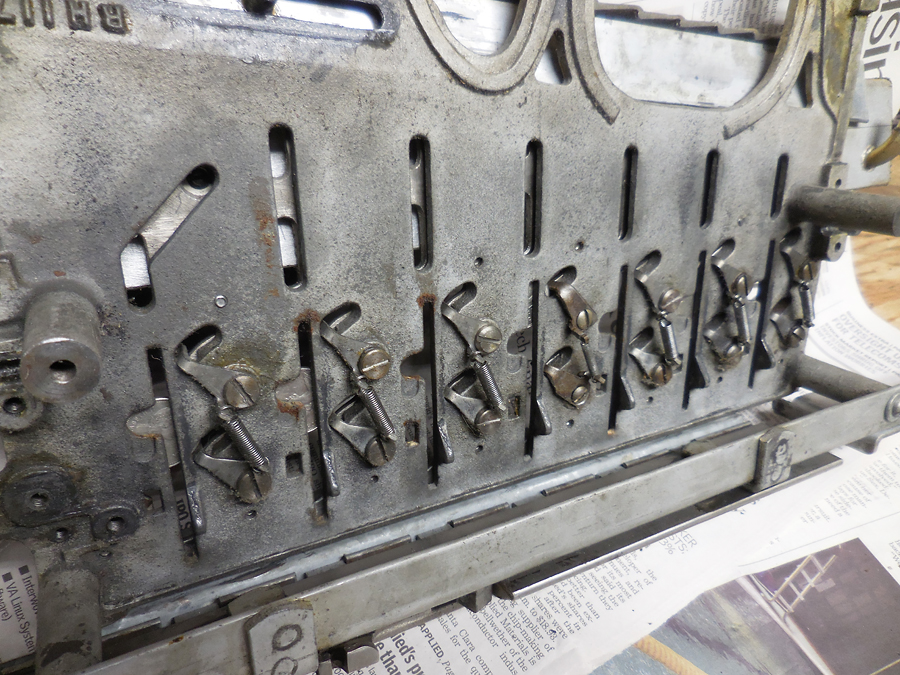

There is a problem lurking in the pictures. Not all the coin fingers are alike.

These two fingers are hand fabricated and use countersunk screws to hold them in place. The original screws were shoulder bolts which when tightened still allowed the finger to rotate freely.

The counter sunk screws and the finger dished to accommodate them were hand fabricated replacements. The operator that made them was clearly proficient at making the fingers. However I wish he had taken the time to make the shoulder screws to hold them in place. While this works, the wear will be rapid and the fingers will fall out of adjustment easily.

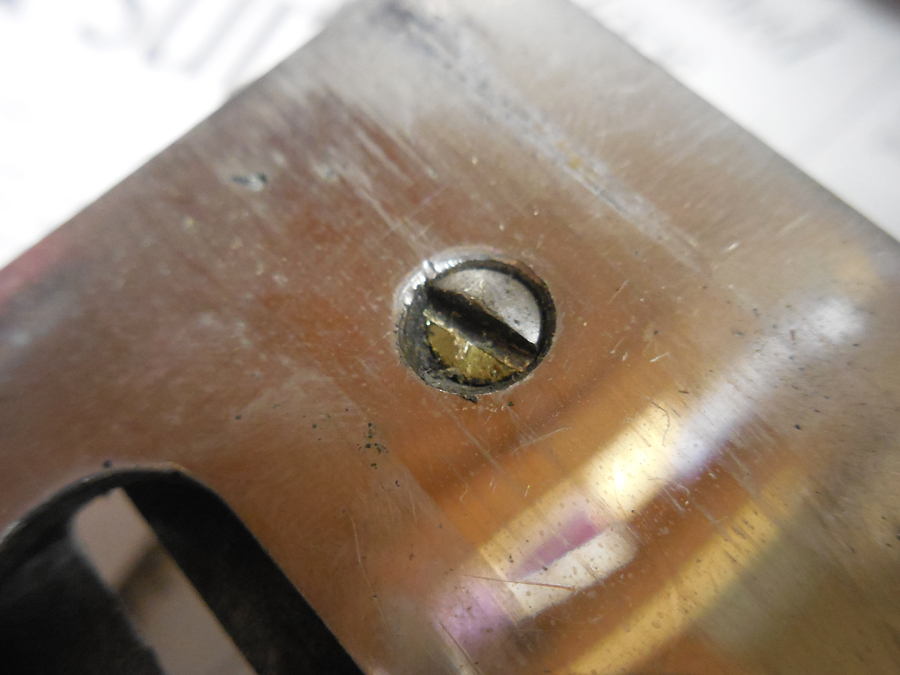

This is one of the many frozen screws I encountered in the game. I was surprised when half the top broke off, a surprised for a brass screw. Luckily heat applied to the casting underneath allowed the screw to be back out without having to drill it.

The brazing is not well done. It is globbed on, way too much, and has suffered a crack. Not sure how long it will hold but decided to leave it in position for now. Unfortunately it becomes much more difficult to truly weld the break if the area is contaminated by the brazing.

The casting is now empty of all attachments. Time for cleaning.