Paces Races Restoration Progress January 30

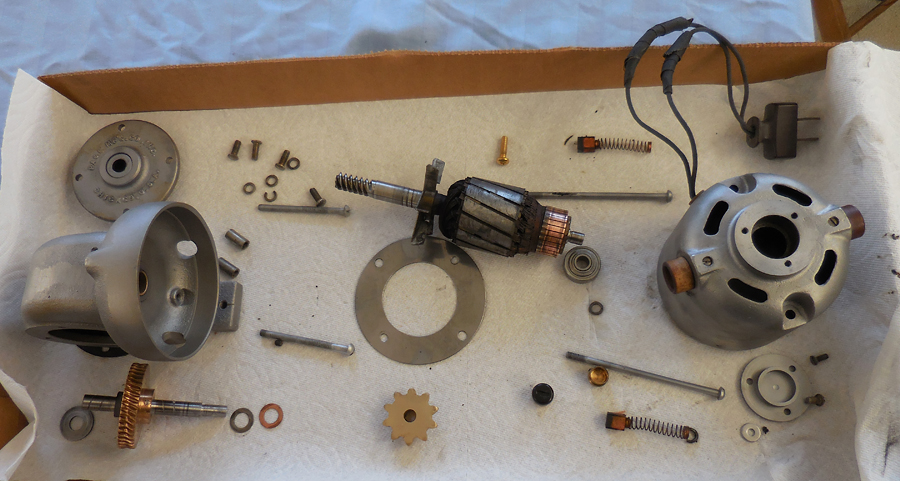

I finished cleaning the motor. I had a gasket from the restoration of the Evans Races so it was easy to fabricate a second one. The commutator was significantly worn and needed to be leveled. I disassembled the shuttle.

I glued a screw head with slot on the top of the brush holder, allowing it to be tightened again. I fabricated a new gasket to protect the cover plate on the bearing race. The gasket on the cover for the helical gears needs to be the correct thickness or the shims need to be adjusted.

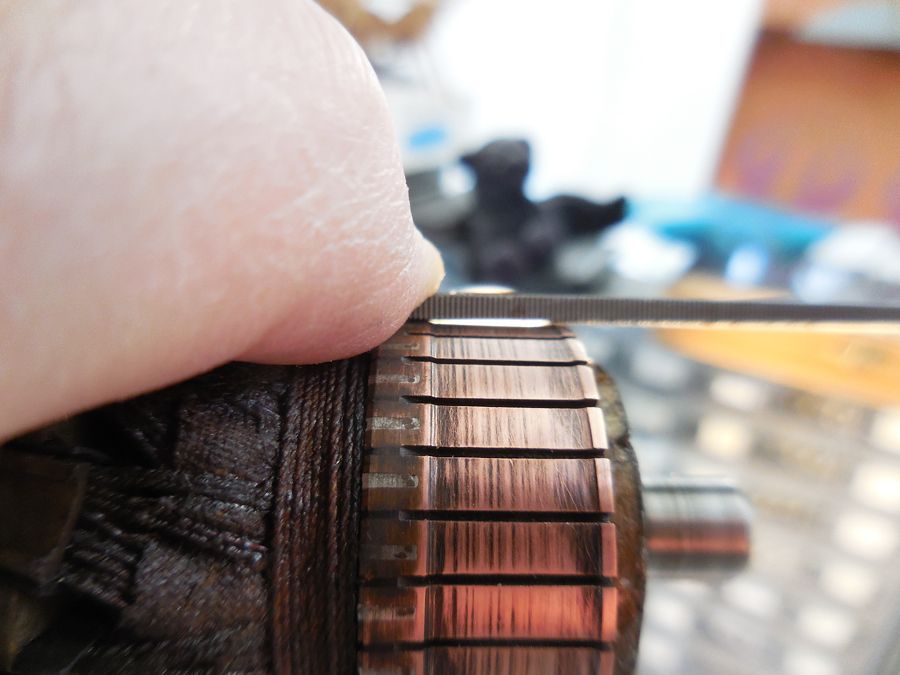

The file across the top of the commutator shows how deeply the contacts have worn. By turning down the contacts so they are level, the brushes have a better chance of making complete contact. Better contact insures the motor will produce the needed power without excessive arcing.

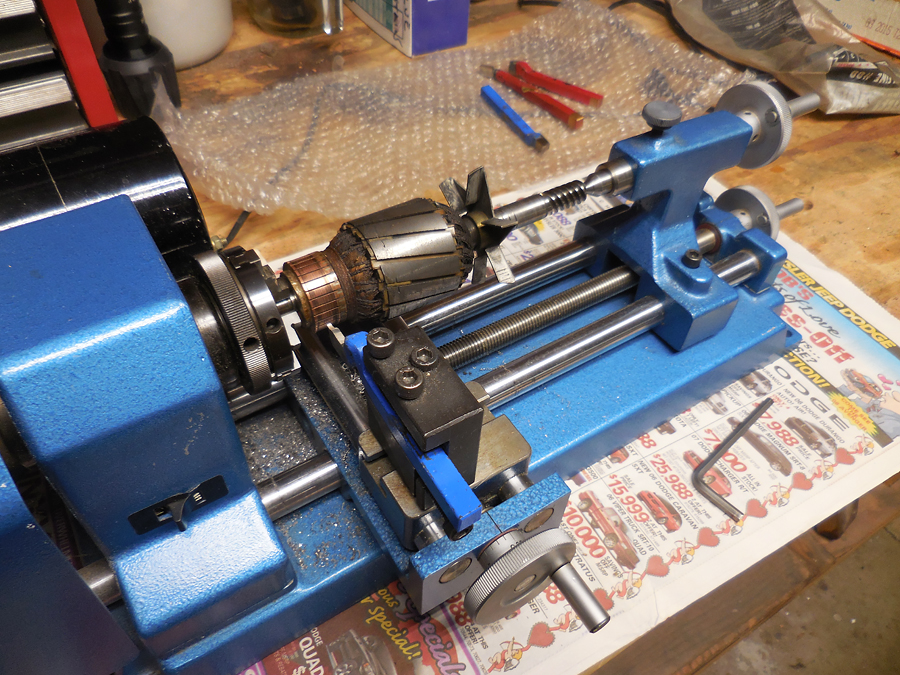

Turning the commutator was easy. I used a jeweler's lathe. The insulation between the contact surfaces tended to melt and gum up the contacts. So progress was necessarily slow to avoid heat buildup.

The reset shuttle goes back and forth the length of the track. The shuttle starts at the starting line and rushes to the finish end at the start of the race. Once the horses finish, the shuttle pulls the horses back to the start line. The shuttle has the ladder chain in the groves top and bottom so by grabbing first the top chain, the shuttle goes one way and then by grabbing the bottom, returns the other way. The lever at the bottom left determines which way the shuttle will go.

One of the fingers that traps the chain can be see in the top right, while the pin at the bottom rides the rail guiding the shuttle.