Roller and Motor Assembly

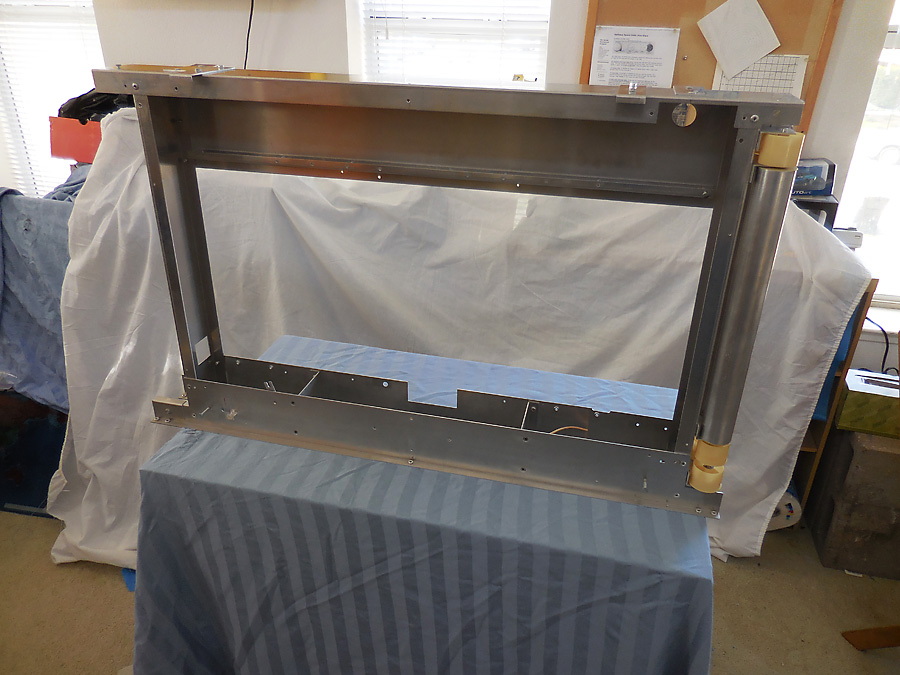

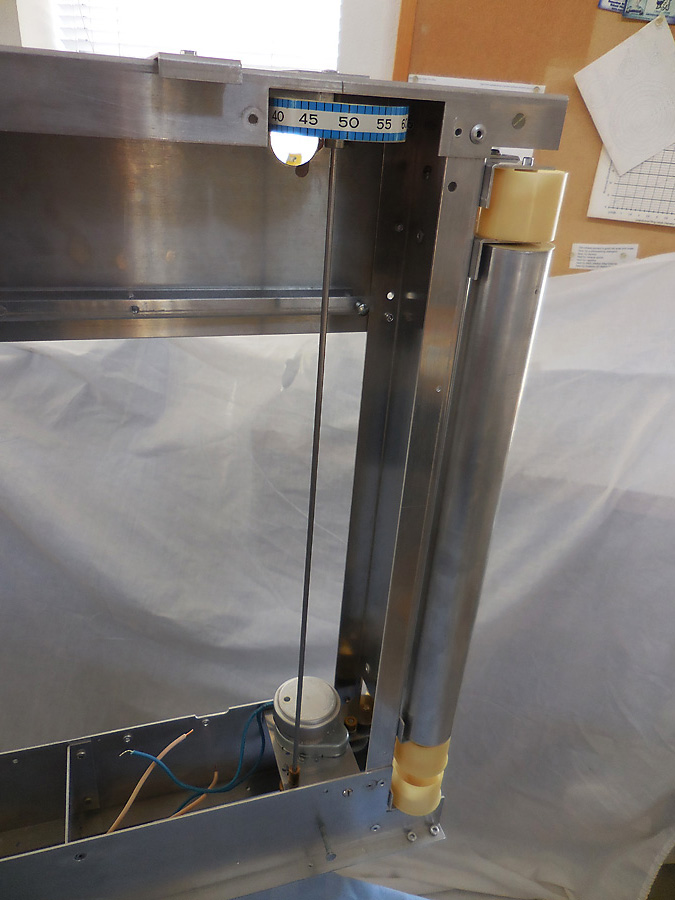

The chassis is clean and ready to have all the components installed, looking at the front. Assembly has already started with the right roller.

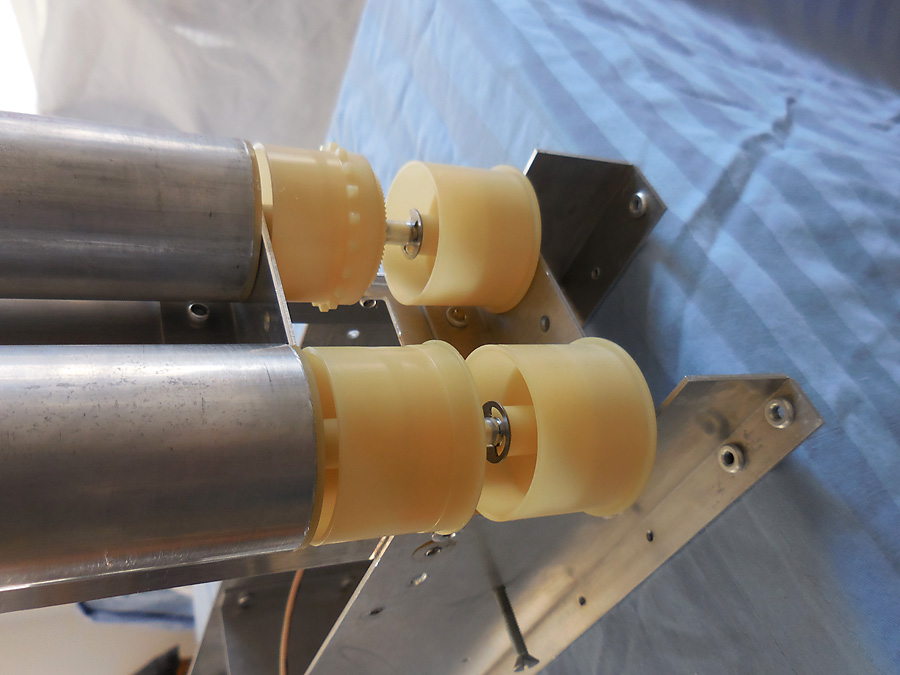

Each of the right rollers consists of a center metal tube, plastic rollers and end caps, and two axles or pinions, one at the top and one at the bottom. Be very careful to identify each component so you can assemble it correctly. It may appear as if each spacer or axle length is identical but they are not. The plastic rollers must turn easily and not scrape on the brackets.

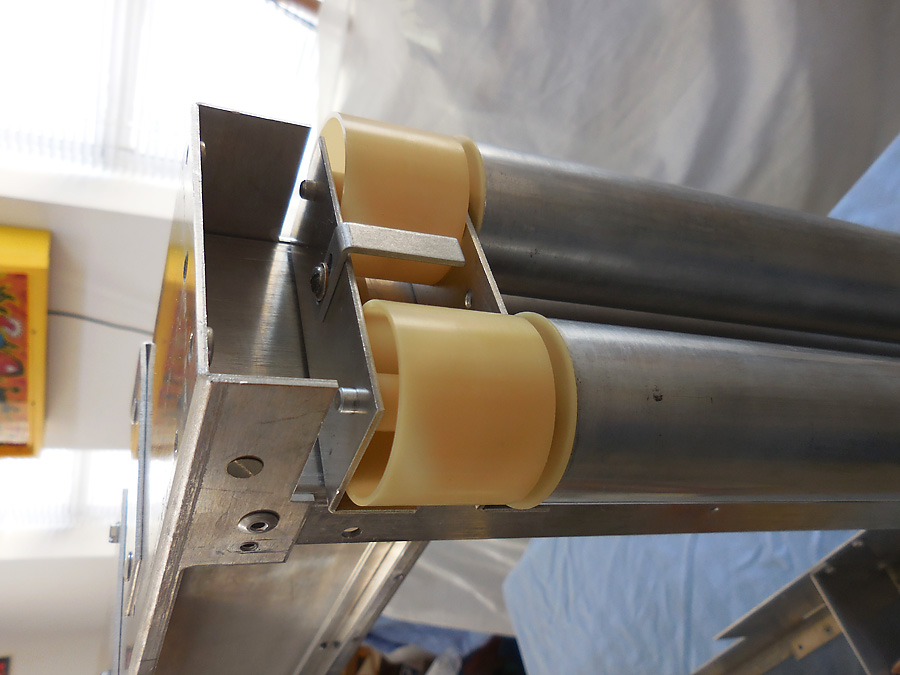

The ends of the metal rollers are different, some have a flange and some do not. Here the metal roller has no flange and the bottom plastic roller does have a flange.

Note the top of the metal roller has a flange and the plastic rollers are smooth.

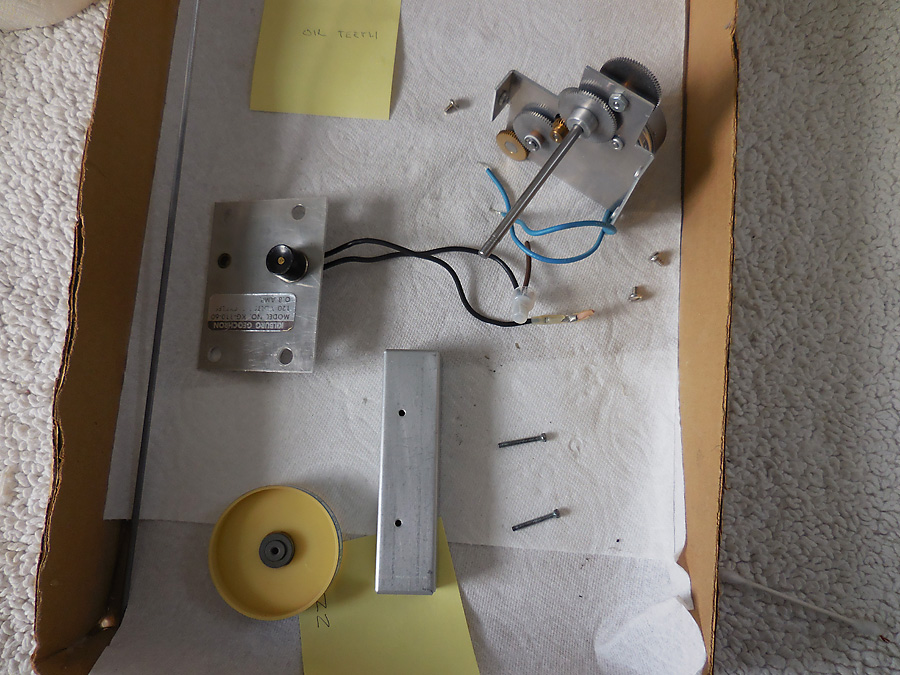

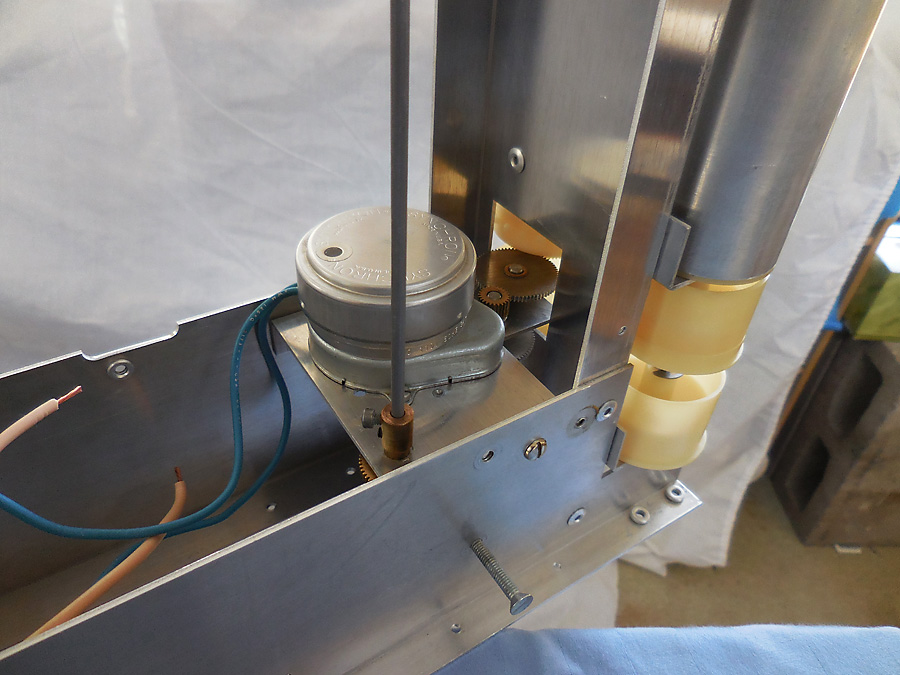

Here are cleaned parts including the map motor, light switch and minute wheel. The metal box with two screws protects the wiring for the lamp sockets.

The Geochron has two Synchron motors, one to drive the map and one to move the sun and shadow. This motor drives the map by engaging the sprocket at the bottom of the roller. The visible, big gear is meshed with the teeth of a gear under the sprocket.

The motor is a Synchron 610 110v 60HZ 3W 1/24 RPH I12LK-6-83 9446. There are a couple of important numbers. 110v indicates our normal line voltage but unfortunately our electric companies supply a higher voltage because it allows them to charge higher rates. The result is that old electronics, designed for 110 volts run hotter. 60HZ indicates the number of cycles per second and is critical to the correct timing of the motor. It synchronizes with the alternating current in order to rotate correctly. Finally the other critical number is the 1/24 RPH which indicates the gear reduction inside the case of the motor causes the output shaft to rotate two and a half times every hour.

This Geochron has a minute wheel, also driven by the map motor. The drive shaft goes from the motor up to the minute wheel. Adjustment is by actually turning the wheel as it is connected to the shaft with a clutch.

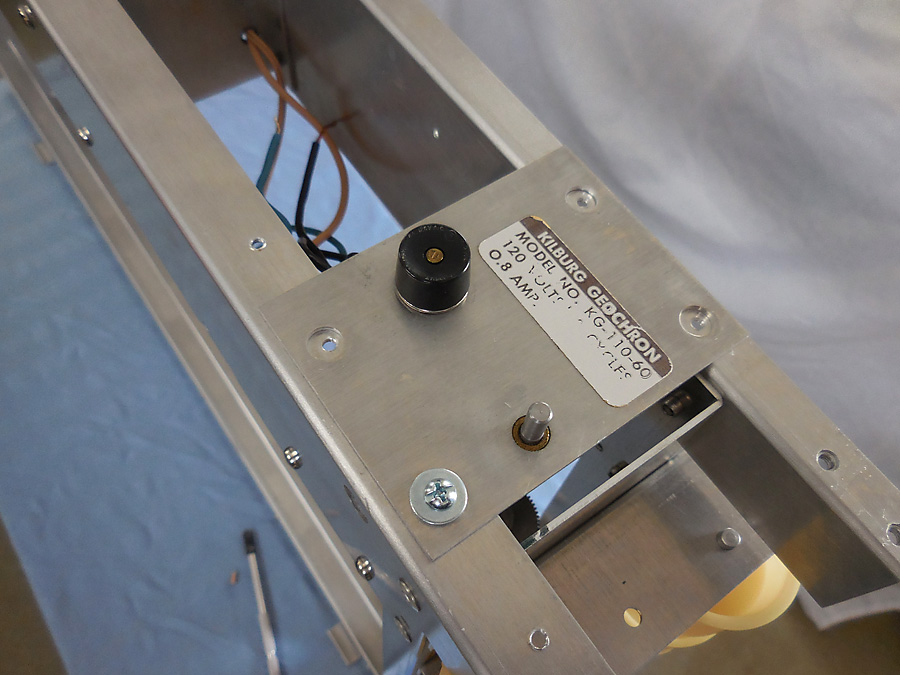

This switch only controls the lights. The axle allows the adjustment of the map, which is actually just setting the time. Kilburg is the original designer of the Geochron and this model is named after him. The serial number is just an embossed piece of plastic similar to that produced by Dymo printers.

Installing the sun and shadow table.