Lotus Supercar Architecture

(roll mouse over number to see frame or over play to see animation)

Supercar Versatile Vehicle Architecture

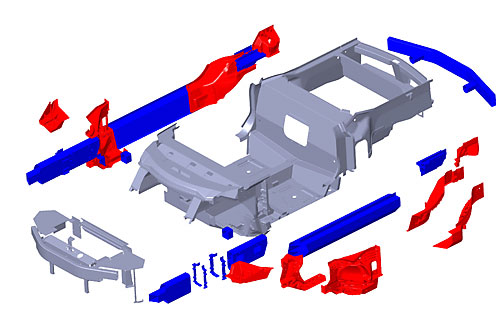

![]() Parts for all cars are common, with extruded parts are in blue, cast parts in red.

Parts for all cars are common, with extruded parts are in blue, cast parts in red.

![]() Parts for super car are choosen and assembled with some sheet metal.

Parts for super car are choosen and assembled with some sheet metal.

![]() Final chassis ready or component installation.

Final chassis ready or component installation.

Lotus introduces Versatile Vehicle Architecture

Date: February 24, 2005 9:06:21 AM PST

To: PR@lotuscars.co.uk

CONTINUING TO CHANGE THE RULES OF NICHE VEHICLE DEVELOPMENT

Lotus Engineering reveals understructure of its innovative Versatile Vehicle Architecture (VVA)

Lotus Engineering, the leading automotive engineering consultancy, is revealing a stunning example of its revolutionary Versatile Vehicle Architecture (VVA) at the 75th Geneva International Motor Show.

Constructed almost entirely from aluminium subcomponents, the understructure reveals the next stage in the development of the innovative technology. The structure reveals the high-pressure die cast corner nodes that are key to an architecture that additionally draws upon Lotus' extensive experience with bonding and extruded aluminium.

"I'm very pleased to be able to demonstrate how far we've come with VVA," explains Steve Swift, head of vehicle engineering. "The understructure proves the concept and we're excited about the possibilities the technology brings to OEMs worldwide."

"We expect that the demonstration of this technology through a real understructure will stimulate yet more interest from OEMs or consortiums looking to produce exciting products utilising cost efficient, proven architecture," he adds.

Versatile Vehicle Architecture

Traditionally OEMs seeking to gain competitive advantage through exciting niche vehicles have to either design a new platform or share one already available. Engineering a bespoke low-volume platform is an expensive, time-consuming solution, whilst sharing a mainstream chassis normally results in compromises in performance and design.

Lotus Versatile Vehicle Architecture (VVA) has been developed to bridge a gap in the investment-volume curve to exploit the benefits of producing at medium volumes but for niche markets, thereby giving the best chance of business case success and favourable returns.

VVA exploits Lotus Engineering's expertise in aluminium, steel and composite body engineering, joining techniques, and vehicle systems integration. This innovative technology offers a fast-to-market, cost-effective approach to differentiated niche products by spreading the development, investment and bill of materials burden across a range of niche vehicle variants, without the compromise that stems from conventional 'platform sharing'

The philosophy is based on the commonality and versatility of key elements of the vehicle structure and body systems across a 'family' of niche vehicle variants, with a combined annual production rate of up to around 50,000 units. Structural components common to each family member are arranged in different configurations in each variant around the ingenious corner nodes.

The great advantage of this technology is that it can be used by one OEM looking to develop a range of niche products, or by a group of OEMs looking to share investment, but still retain a high degree of end product separation.

"We believe it is a technology that provides solutions to a wide range of manufacturers," says Swift. "The worldwide vehicle market continues to sub-segment at a rate greater than its overall growth, leading to lower volumes per vehicle variant. OEMs are looking for architectures that give them a superior investment return with a high degree of product separation. VVA gives them that opportunity"

Understructure Construction

The understructure is aluminium riv-bonded, consisting of high-pressure die-castings, stampings and extrusions, and uses advanced assembly techniques, including adhesive bonding, self-piercing rivets and flow-drill screws for construction.

The self-piercing rivets are used in a similar way to spot welding on a conventional steel shell, with the flow-drill screws used for single-sided access on closed sections. Both suffice to hold the structure together during the bonding cure cycle, and prevent adhesive joint peeling in the event of a crash.

The heat-cured high strength structural adhesive is the main joining medium, and used in combination with the mechanical fasteners, produces an immensely strong, durable joint and a lightweight shell with exceptional torsional stiffness.

Lotus Cars Product

VVA is the technology that will be used by Lotus Cars for a forthcoming range of sportscars. The understructure exhibits the principles by which Lotus will engineer its own product

Example VVA families

The following represents illustrative VVA families that could be

achieved:

- Family A

- Front engine 4wd crossover 15,000 / year

- Mid engine rwd supercar 5,000

- Front engine rwd coupe 10,000

- Front engine rwd saloon 20,000

- Family B

- Front engine fwd coupe 10,000

- Front engine 4wd suv 25,000

- Family C

- Mid engine rwd coupe 5,000

- Front engine fwd saloon 25,000

- Front engine 4wd crossover 30,000

Editor's Notes

Lotus Engineering is an internationally recognised automotive engineering consultant based in Norfolk, UK. Its global facilities include those in Michigan, USA and Kuala Lumpur, Malaysia, and offices in Germany and China. It provides comprehensive and versatile consultancy services to many of the world's car manufacturers and tier one automotive suppliers, from initial concept and project design through development to full

production prototype build.

For further information, please contact:

Robert Tickner

Head of Marketing & PR

RTickner@Lotuscars.co.uk

+44 1953 608846 (office)

+44 7715 485576 (mobile)